The double hitter: ZSU-57-2 in Bosnia

This is a long article. If you’re interested in a particular section only, make your life easier and use the links below:

My previous project, the Ferguson tractor, was a lot of fun. But now I going into the opposite direction. Last time I really enjoyed the liberty of building a civil, random vehicle not restrained by any historical facts. Now I’m going to let those restraints hit me big time.

Recreating a real vehicle from a photo is at so many levels the biggest challenge in this hobby. It means problems. And you’re going to stumble against problems every step of the way.

You need to analyse the photo, look at the vehicle’s distinctive features, put it in a historical context and understand all the factors that made it what it is on the picture.

And then you have to recreate it all…

I’ve always wanted to do something like this, firstly because it’s an ultimate challenge, and secondly because I really love to go through old photos, to analyse them and look for all the little details. It’s like a riddle that needs to be solved.

I took some time searching for a subject of this project. I wanted a fair challenge but not a ‘mission impossible’ kind of stuff. But when I came across this monster, I was looking no further.

The Soviet ZSU-57-2, a double-barrelled killing machine. It wasn’t an obvious choice because I’ve usually concentrated on WWII subjects in my previous builts. But just look at it, this thing is brutal.

A PINCH OF HISTORY

During the WWII the air force for the first time proved its tactical and strategical value. It became clear that the ground units needed constant AA cover or they would face obliteration.

Both sides of the conflict started to develop the idea of a self-propelled AA-gun that would accompany the advancing troops during the whole campaign- stationary AA defence just wasn’t enough anymore. Just before the end of the war, the Germans sent to fight one of the first mass-produced SPAAGs: the Wirbelwind. The Hungarian 40M Nimród was another contestant in this race.

ZSU-57-2 was Soviet Russia’s second attempt to create a self-propelled anti-air cannon. The first one was ZSU-37 that managed to get into the fight during the war but was a flawed design.

ZSU-57-2 was a much better construction armed with two 57mm S-68 cannons (hence its name). The design was based on T-54 tank, with the chassis shortened to four wheels at each side.

ZSU-57 had two killer autocannons and a decent firing range of 4000 meters, but the lack of modern equipment such as a radar soon made it obsolete. The Russians started to develop a more sophisticated vehicle- ZSU-23-4 Shilka. ZSU-57 on the other hand was offered to satellite countries and Soviet allies. The double-barrelled monsters soon spread across the world from Poland to North Vietnam.

THE ANALISYS

First thing I did was to take a closer look at the photo. It didn’t take me long to establish that this particular ZSU-57 fought in Bosnia not so long ago. (to be honest: it is said so on the wikipedia page where I found the photo…)

The conflict in Bosnia was a dirty, dirty war that tore apart former Yugoslavia in the ’90s. This particular vehicle served in Bosnian Serb militia, forces loyal to Serbian cause. I don’t want to go deeper into this- trust me, it was a nasty war. Let’s talk about the tank instead.

The vehicle on the photo looks like a Soviet version of ZSU-57 (Eastern German tanks had different fenders and equipment). It was obviously modified including the superstructure on the turret and the rear net box replaced with an armoured cover. Also, the vehicle had its front and rear fenders removed. There is an ammo crate attached to the front armour and there is something on the turret that appears to be a machine gun covered with a tarp.

Let’s concentrate on the superstructure for a second.

I’m guessing it’s an improvised armour that was meant to cover the crew from aerial attacks. It makes sense as the Serb troops faced NATO jets blazing them from the sky during the Joint Endeavour Operation.

I initially thought the thing is made entirely of metal plates, but then I realized these are rubber sheets.

As you can see below the Serbs had a thing for covering their tanks with rubber. I don’t understand the purpose though. If it was a way of hiding the vehicle’s heat signature against NATO rockets, I doubt if it was a successful trick. Or maybe it somehow protected against RPG-style rockets? Can someone explain?

The rear structure on the turret was also meant to provide additional cover for the crew. At the same time it served the similar cause as the original net box- it was used to gather the empty shells leaving the cannon. We can’t see much of it from this angle but it’s very rusty and was made out of armour plates.

I can’t really identify the front ammo box, but it is definitely of soviet origin. It has some substantial damage suggesting that it also was used as an additional protection from projectiles. I found a photo of a similar crate that will give me inspiration during the construction.

The tank almost looks like it was painted in some sort of sandy yellow shade. But the sunlight coming from the front makes the colour lighter than it really is. In fact it’s rather a standard pale green used in Yugoslavian army. Take a look at another Serbian ZSU.

OK, I’m finally done with the analysis. Let’s go back to the actual modelling, shall we?

THE MODEL

There are two models of ZSU-57 on the market: Trumpeter and Takom. I finally went for the latter assuming a newer model will be a bit more advanced. Also, Takom offered the decals for my version of ZSU which was very convenient.

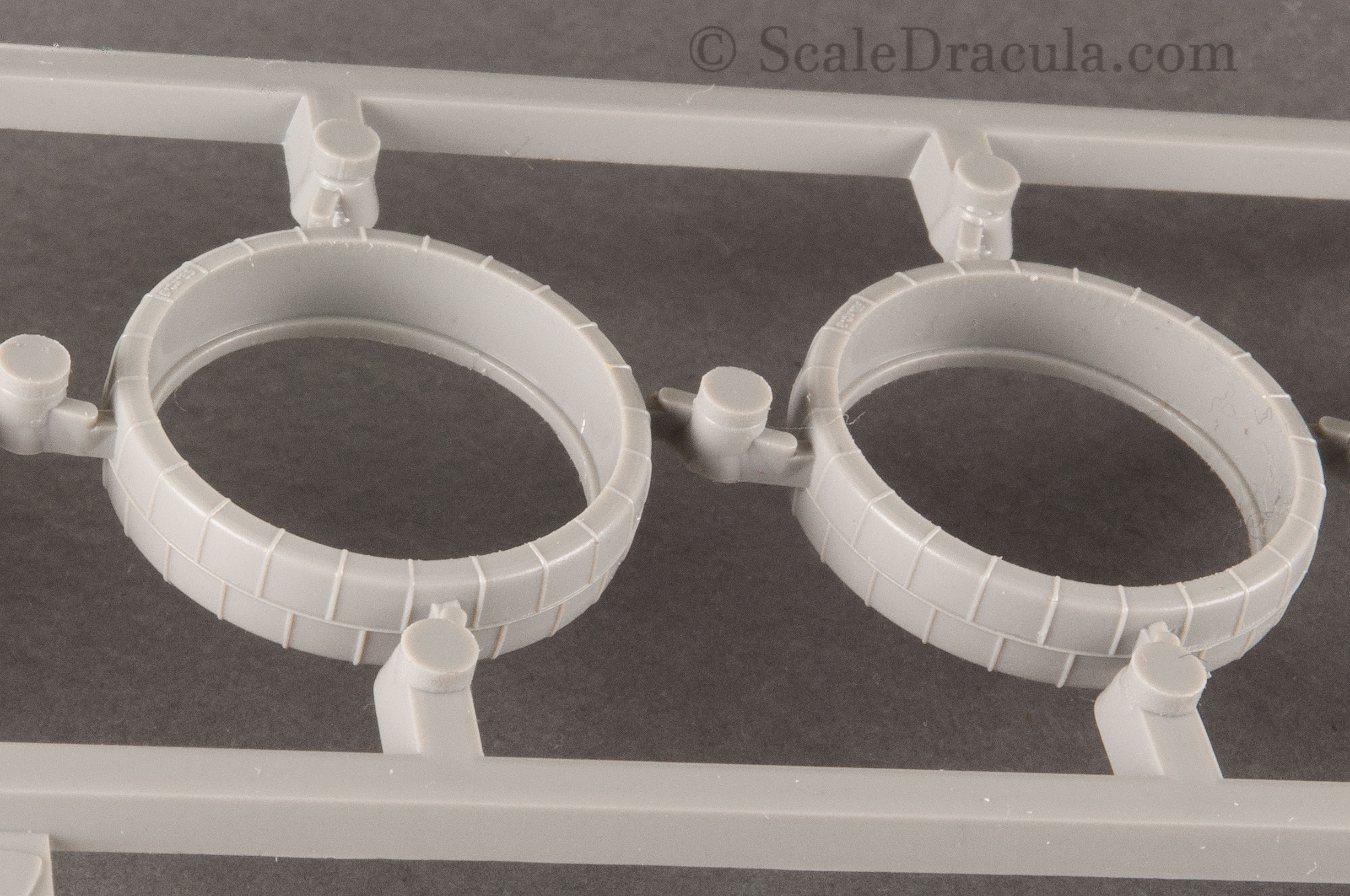

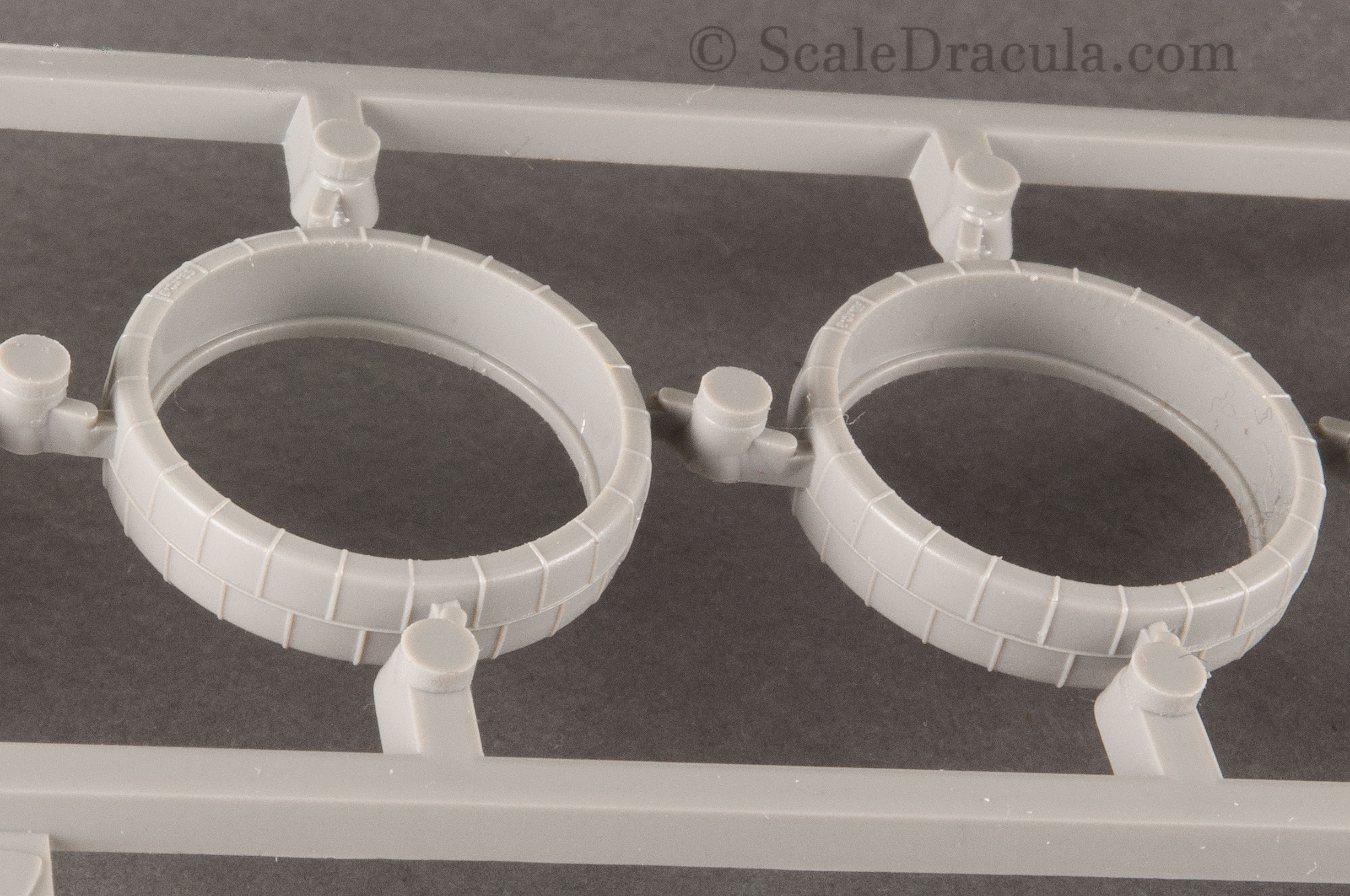

Generally speaking the kit is very good, with high quality details and precise fit. Apart from a tonne of plastic, the box contains a little sheet of PE parts, a vinyl dust cover and a towing cord. I couldn’t help noticing a really nasty flash on some round parts, but overall I really like the kit. I feel like the philosophy behind it was: ‘let’s give them a kit good enough to be build without aftermarket parts.’

As much as I like this idea, I just had to buy some additional stuff, right?

I really like to use metal barrels, and especially in this model I think they are a must. The double cannon is what makes this tank to stand out from the crowd.

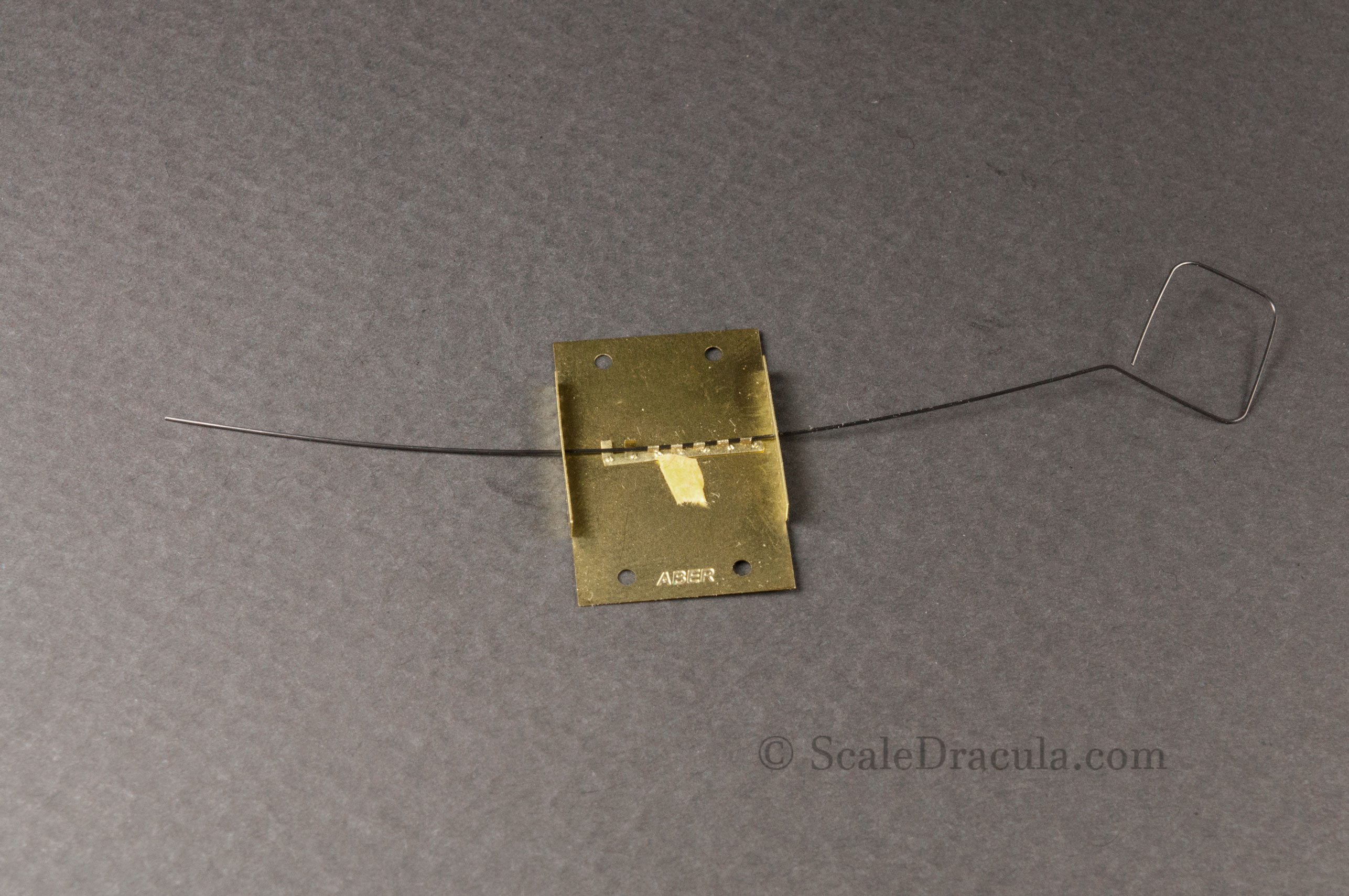

I bought an excellent kit of metal barrels by Aber. Take a look at the comparison.

I’ve always suspected that guys from ABER are a bit crazy. Look at the size of the smallest rivet. LOOK AT IT!!!

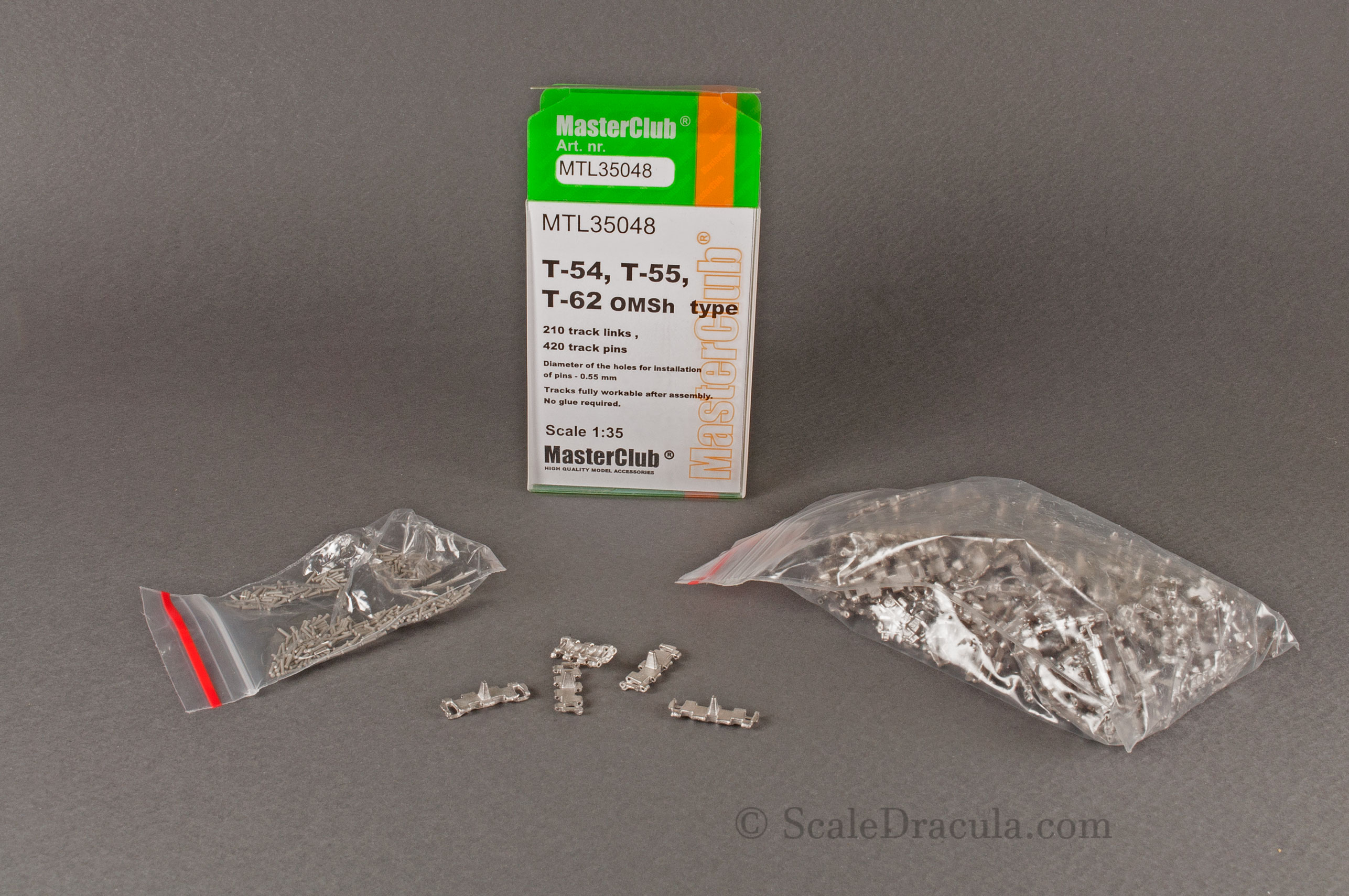

I’ve also acquired a set of movable metal tracks by MasterClub. I’ve been using their products for a while now and I must say I’m really happy with the quality. For linking the tracks together you use tiny resin pins instead of a wire. It is a very tedious work, but the effect is really spectacular.

Just to be clear: Takom has done a very impressive work with their plastic tracks. I’m sure you can use them and get a fantastic result. But I really like the comfort of working with metal, movable tracks. Cleaning the plastic ones is a nightmare I’m always trying to avoid.

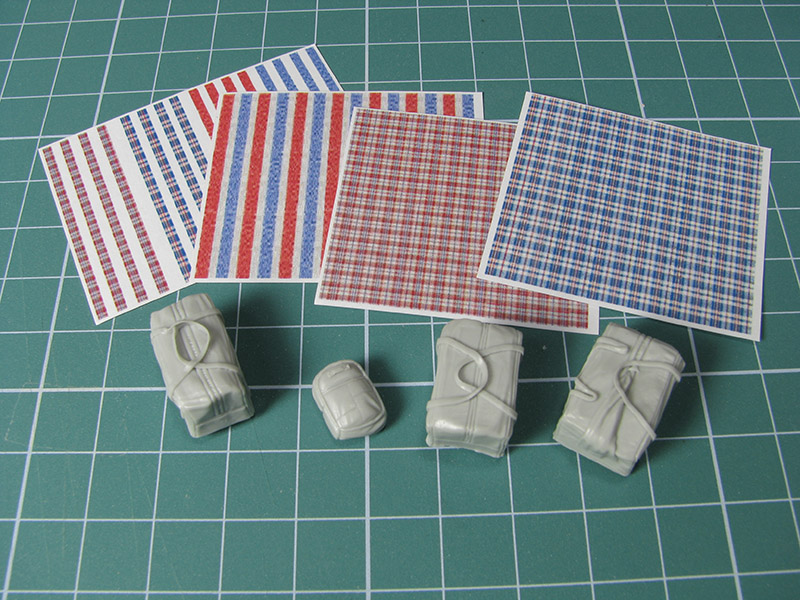

Last but no least, I decided to buy some additional items I will scatter on my ZSU. I often do it to give my usually green tanks a punch of colour and some personal touch. I’ve chosen a towing cable (the one in the Takom kit isn’t very good), a funnel with a bucket, and a set of Eastern European cargo bags. Because nothing says ‘slav’ quite like this colourful market bag. All of theses items were manufactured by Eureka XXL (photos below are from their site) and are of very good quality.

THE CONSTRUCTION

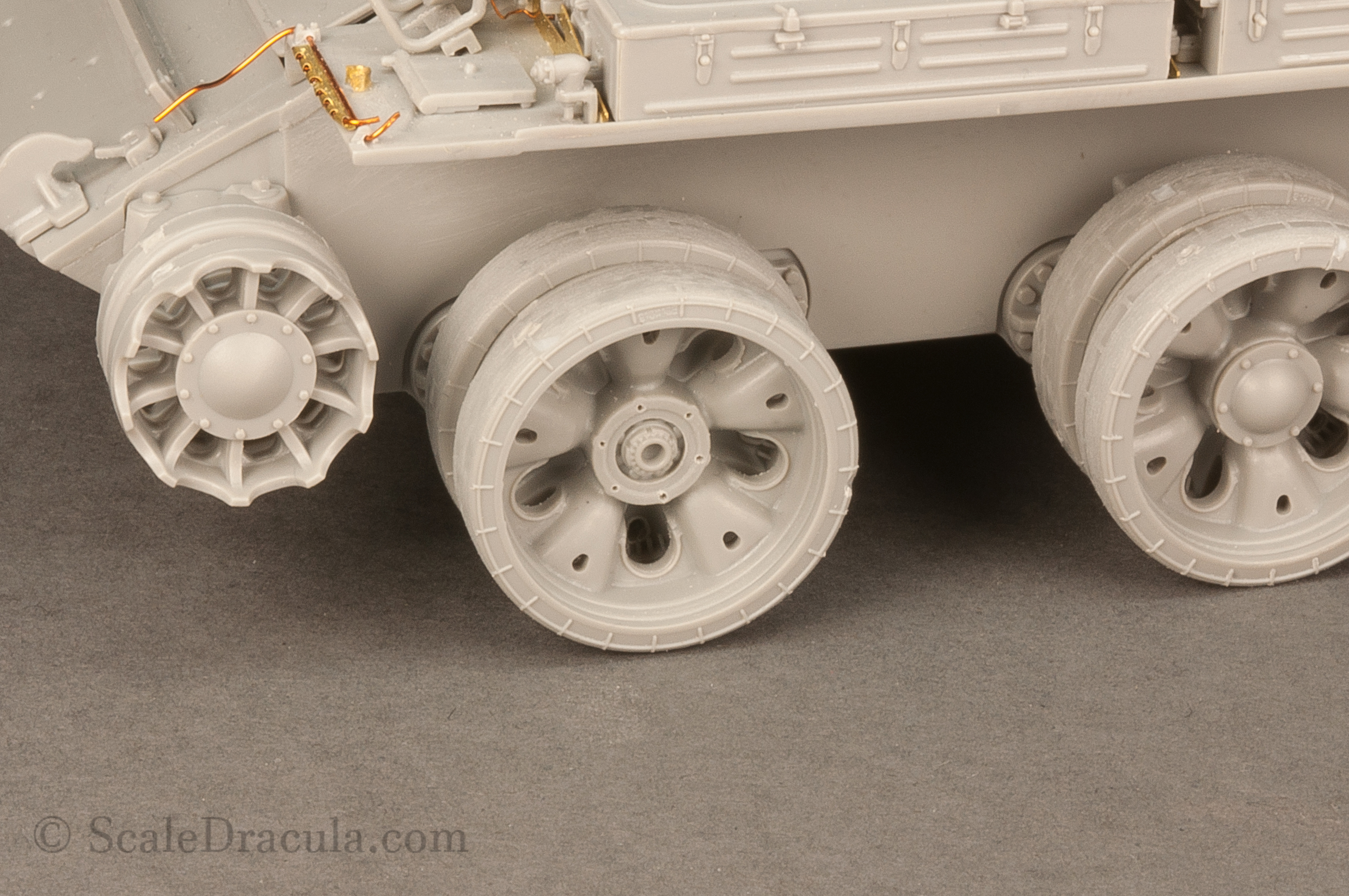

My version of ZSU-57 will need a lot of scratchbuilding, but I left it for later. I started the construction with wheels and undercarriage which is boring, but well, it has to be done. You might want to leave the tyres unglued for easier painting later. As I’ve already mentioned the tyres have a wonderful tread which you’ll sadly need to get rid of unless it’s a brand new tank you want to recreate.

The fit on Takom’s model is really spectacular. I built the main hull without any problems. Then I ignored the instruction and went directly to the fun stuff: the cannons. Takom went to town with the details on them and it’s pretty much a model by itself. Again, the fit is very good but the job is tedious: it’s over 150 part to clean up and assemble.

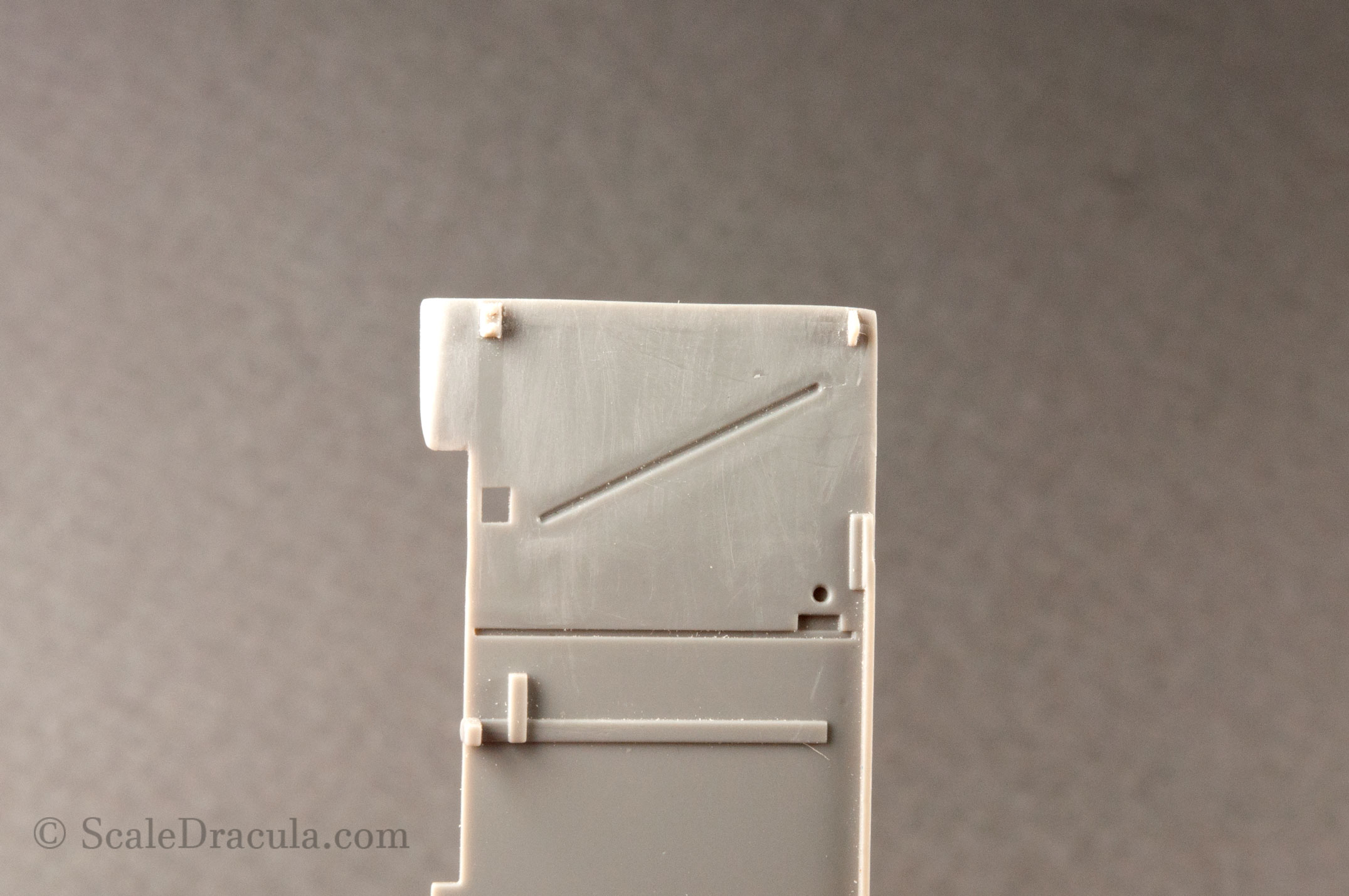

I needed to take a break at the fenders to consider my options. The plastic ones are naturally a little bit too thick and unrealistic. On the other hand, I don’t know of any aftermarket kit of PE fenders for ZSU-57. And I wasn’t hardcore enough to build them all by myself.

I decided to use the plastic fenders but thin them down considerably and make new hinges as well.

I sanded both ends of the fenders from the bottom side. A centimetre or so (pardon my metric) will be enough to create a good visual effect.

Then I cleaned the upper side from any details. The original hinge had to go anyway.

The rear fender was a little bit more complicated, because I had to cut off the lower part. Easy thing to do though. I used a razor saw.

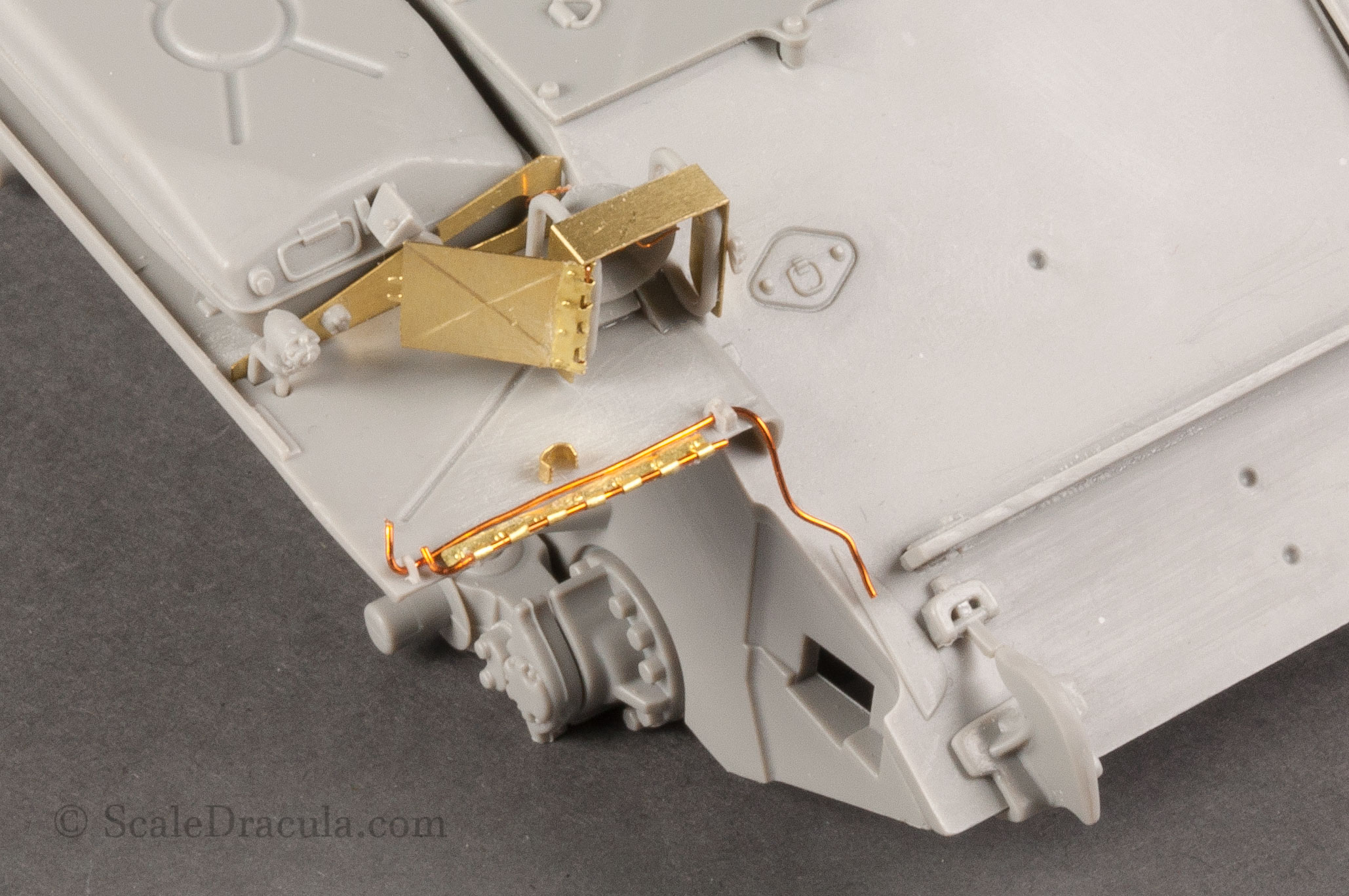

I made the hinges using a PE set from ABER which conveniently comes with a magical ‘bend-a-hinge’ device.

Then I used some copper wire and random PE part to finish the hinges with all the details. Is the effect worth all the extra work? I have my doubts. Takom has done a pretty good job on those parts.

The rest of the fenders I built according to the instruction manual. From now it’s really some basic modelling. There are some PE parts along the way, but they are super easy to work with.

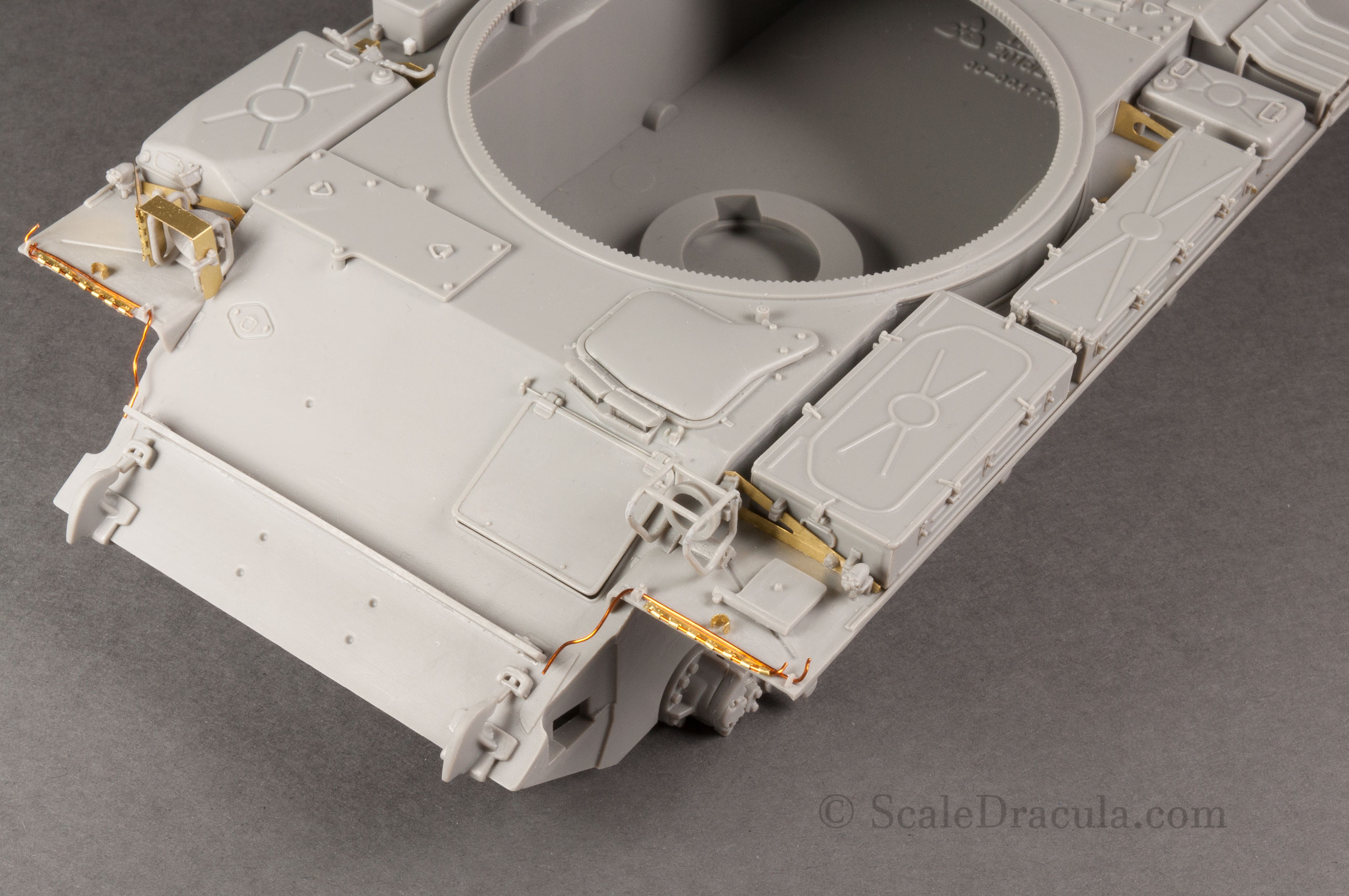

On the back of the vehicle I added some wires running to the position lights. Again, very easy stuff.

From now on the kit pretty much builds itself. So let’s talk about something more interesting, shall we?

It was the time to start building the custom parts for my version of ZSU-57-2. I’ve already talked about the mods in the introduction to this project.

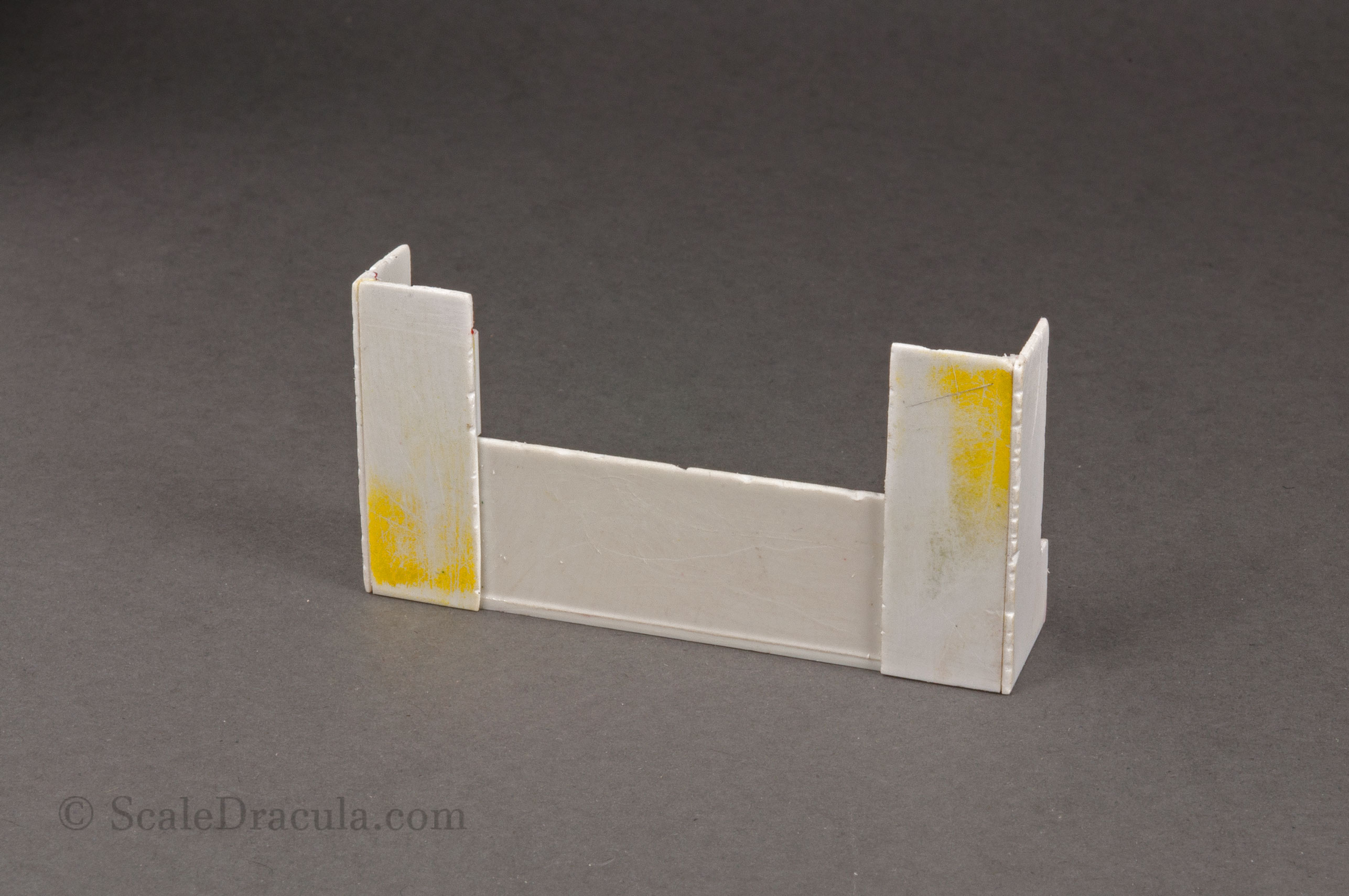

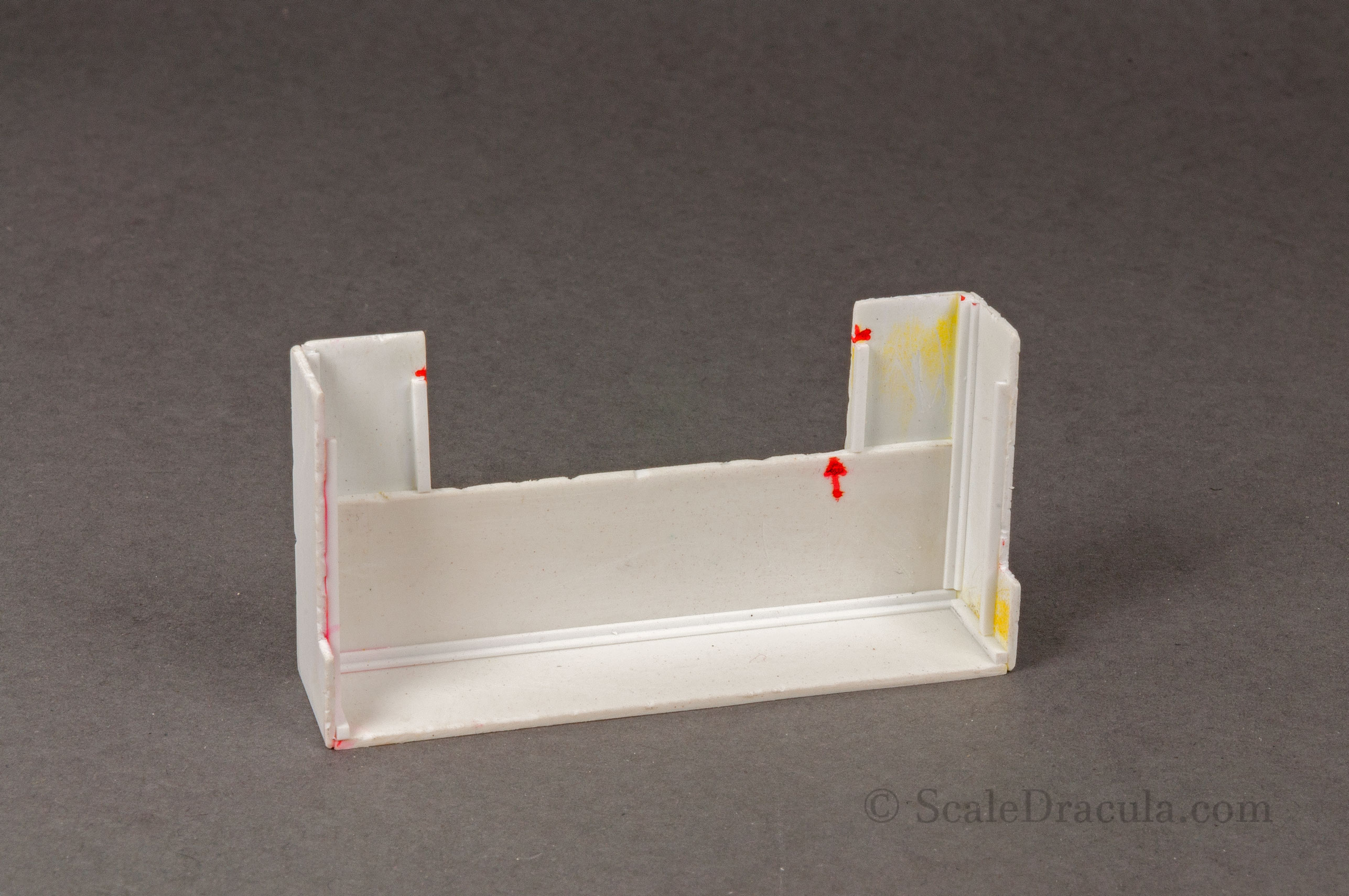

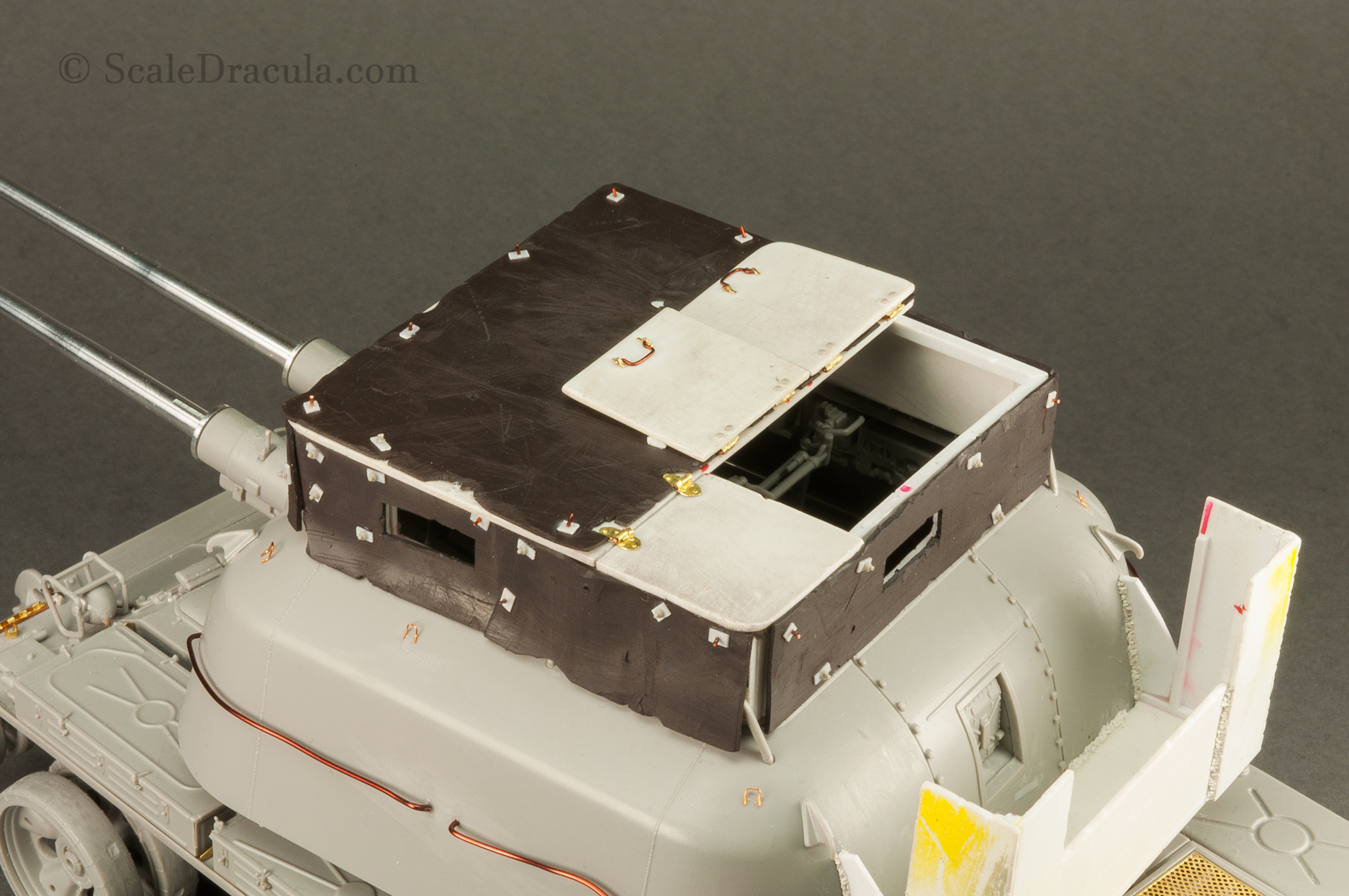

First, I looked at the armoured structure in the back of the turret.

There’s not much info to work with here. I could have been the original net box only reinforced with metal plates. But I imagined a symmetrical, improvised structure that was put together with metal sheets and then welded to the turret. I’m not sure if it’s 100% historically correct, but it sure will be more interesting.

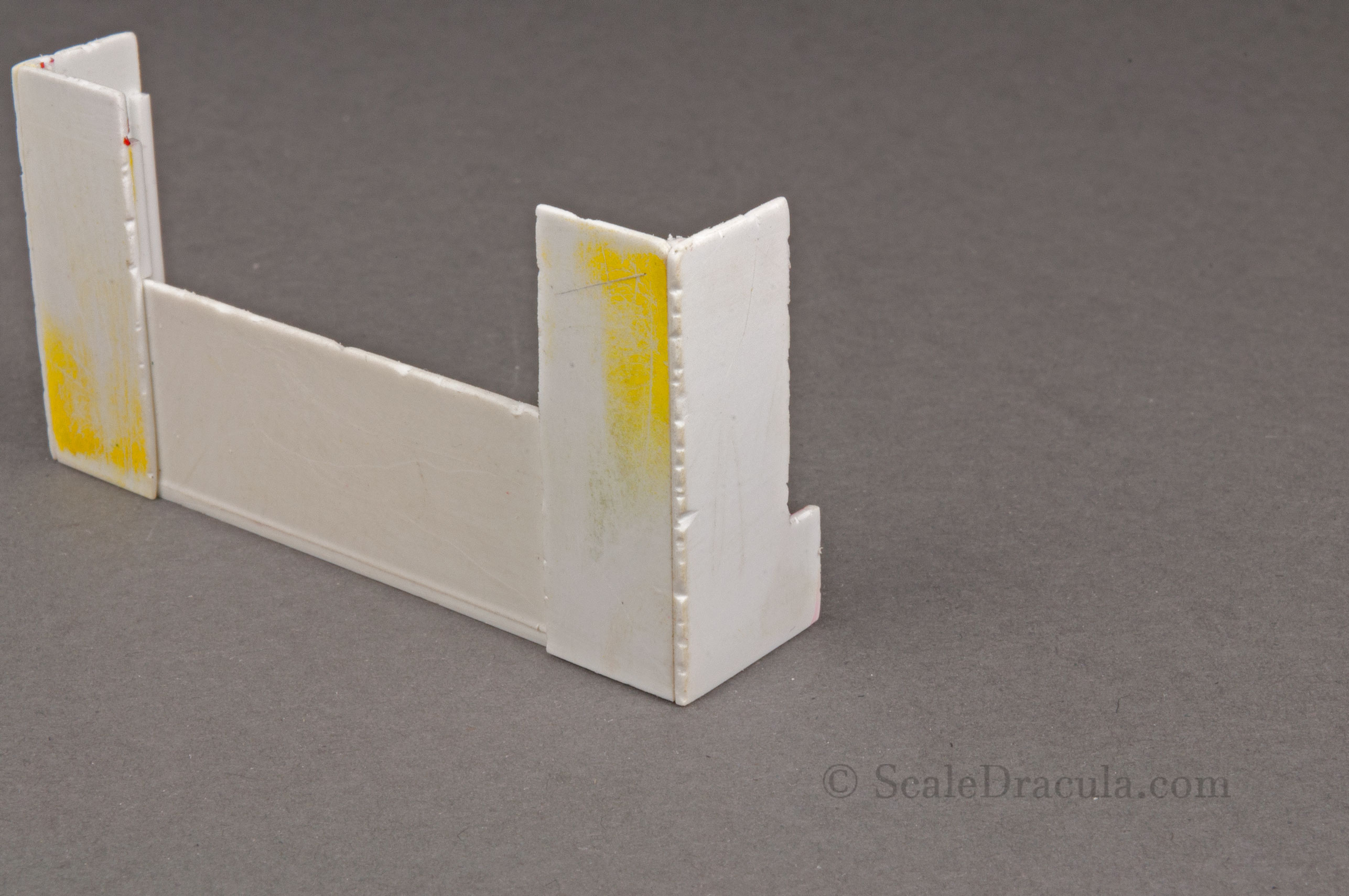

I built the structure from styrene sheets and rods made by PLASTRUCT. You can probably save some money and find parts like this in your ‘one-day-I-will-definitely-need-that’ stash. But on more demanding project I would advise purchasing some dedicated parts. They are really cheap.

I took some time to make imperfection and dents on the metal. It is a junk yard build after all… I used a hobby knife, file and some sanding paper. The part is finished!

Let’s move to the upper structure. It is a little bit more complicated, but I’ll try to explain it step by step.

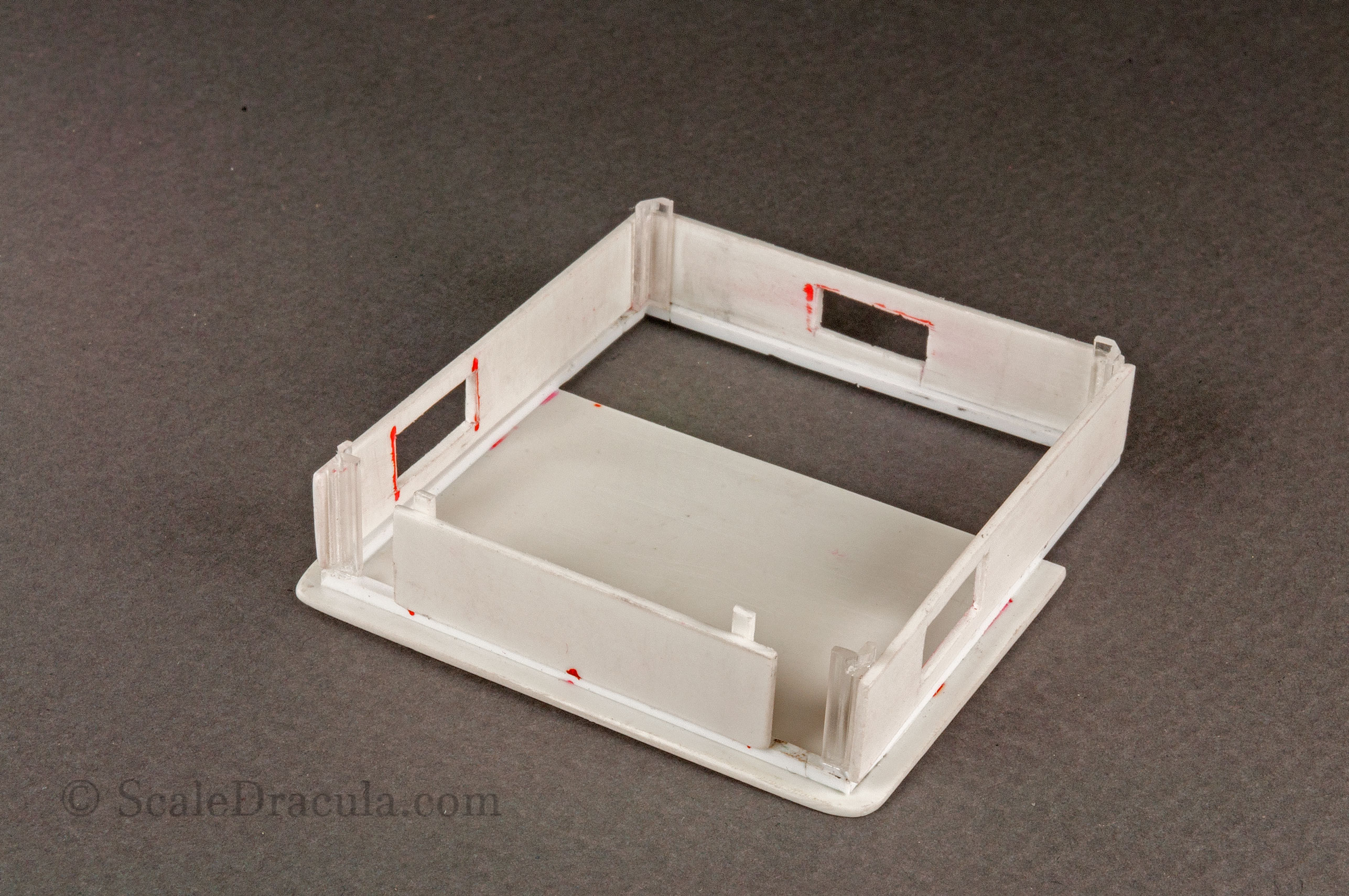

I created the basic shape of the roof again using PLASTRUCT products. Obviously I didn’t have any blueprints of the structure, so I had to work using my best judgement and logic. Here’s a photo of the initial frame built with plastic rods.

Then I covered the sides and the top of the structure with some styrene sheets. I assumed the roof would likely by armoured to provide cover for the crew. I also decided the structure will have some hatches at the back. Their location and shape is my pure imagination. The superstructure might as well have been half-open, but the hatches will provide some extra details.

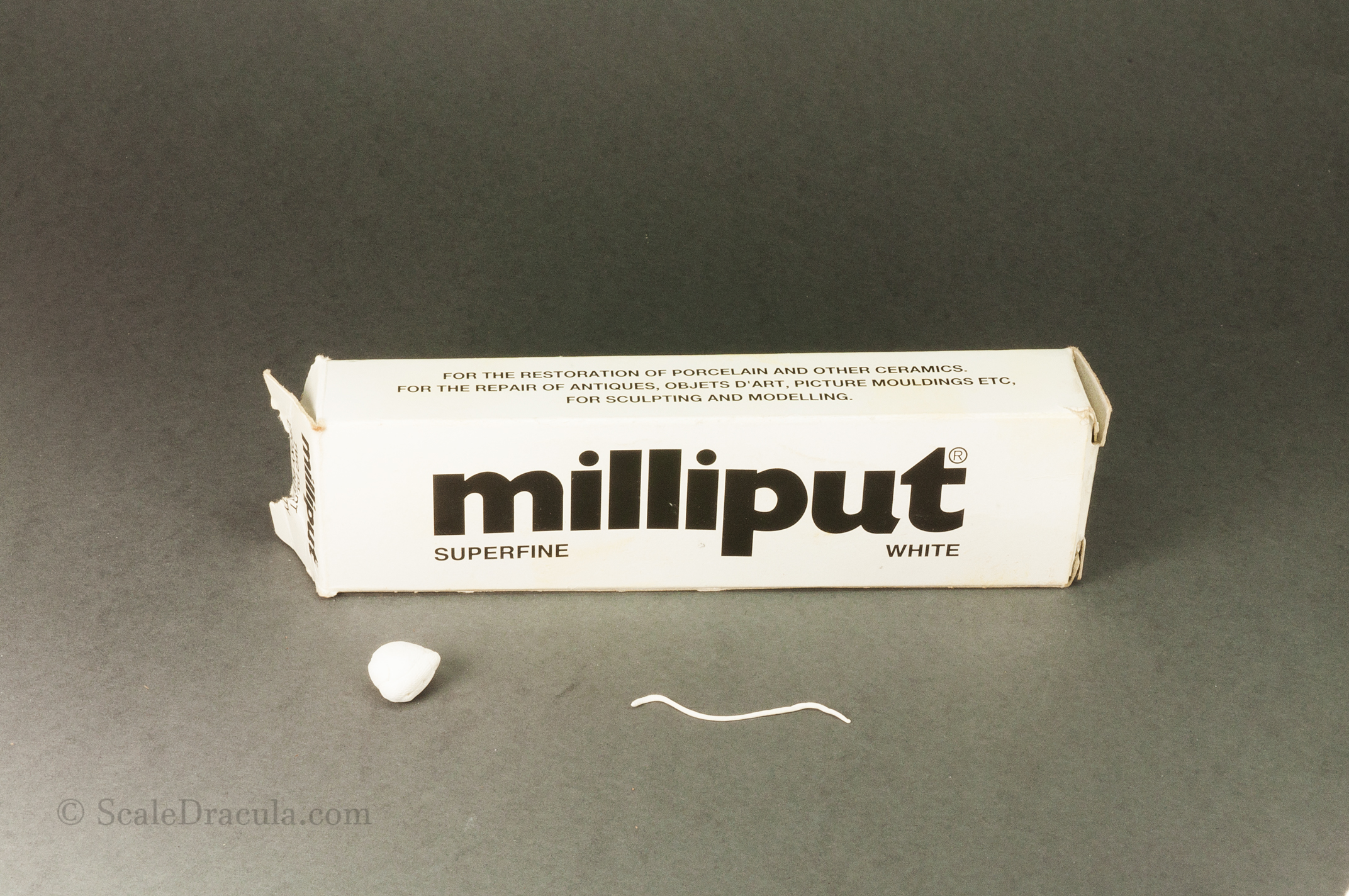

Next step was to recreate the rubber. I took some time thinking about what material I should use. I initially thought I could roll thin sheets of Milliput and cut it from them. But it would require hours of hard work to get it right.

But then in struck me. If I want to make rubber, why don’t just use… rubber? The simplest ideas are usually the best. I finally found out that something called magnetic rubber would suit my needs just fine. It’s a material used to produce little magnets you probably stuck on your fridge. It’s pretty cheap, easy to get and comes in different sizes and thicknesses.

For my project I chose 0,5mm and 1mm thickness (0.019 in and 0.039 in respectively, my dear metrically impaired friends…)

Magnetic rubber is extremely easy to work with. You can cut it with a hobby knife. It’s pretty resilient and can be formed into different shapes. But on the other hand, you can easily make some wear signs using file or sanding paper.

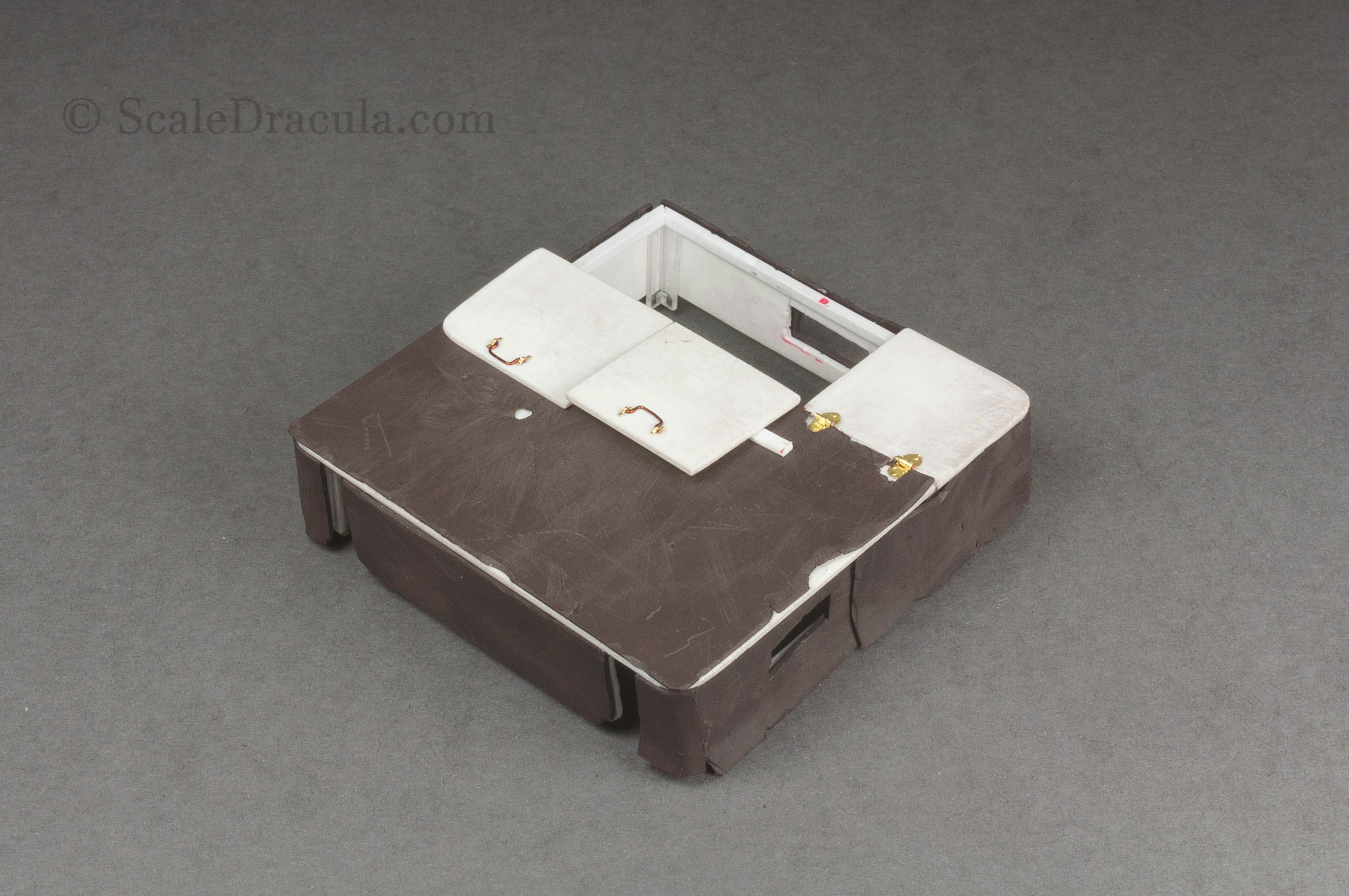

I started to attach rubber parts to the structure. A slow drying CA glue is perfect for that task.

It’s time for the first dry fit. The part sits pretty well and I think it doesn’t look bad considering I didn’t have any exact dimensions.

I made additional details to the part. Hatch handles and hinges were constructed from copper wire and some leftover ABER parts.

Last but not least I added bolts to accompany the hinges from the other side. I made them with some old MasterClub track pins. You may think it’s just an irrelevant detail, but those tiny things are going to shine after the painting.

Then I started to make metal pads that held the rubber sheets. First I glued on some small plastic rectangles. Then each one had a hole drilled in the centre. After that I had to glue a piece of wire to….. EVERY. EACH. ONE. OF THEM.

Repetitive actions like that are my least favourite aspect of scale modelling. But well, it has to be done.

Moving on. I came back to the main hull to attach the already built rear structure.

As you can see below I also made grab handles using a wire. The wire looks much better than plastic parts and can be easily shaped into any form you want.

Quick tip

It's often convenient to use wire in your models, for example to recreate handles or engine cables. Always drill holes that you will put the wire into. This will ensure a more durable joint.

It’s time to do weld marks one the metal plates. I used some modelling putty and a hobby knife. Look at the pictures below. I think they are self-explanatory.

Let’s take care of the last piece of scratch-building. I hope you haven’t forgotten about the ammo box at the front of the vehicle.

I didn’t manage to fully identify the box. But it’s definitely an ammo crate of Russian origin.

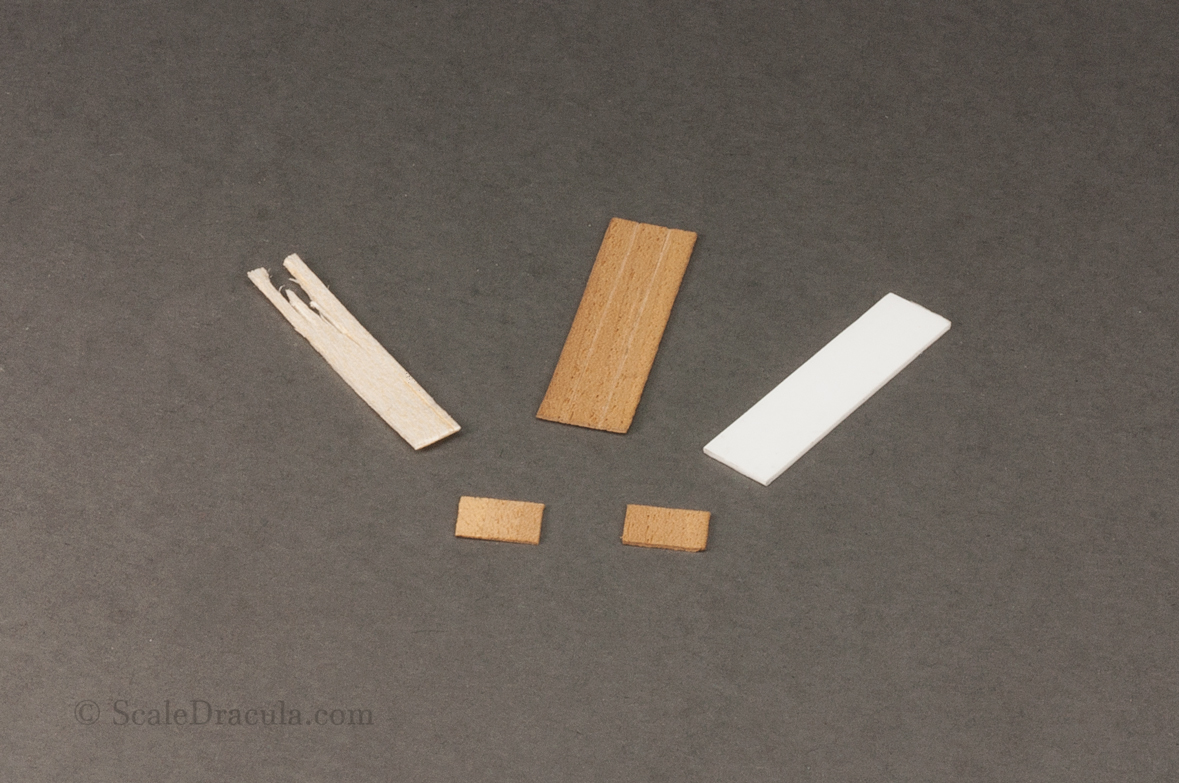

What else would be better to recreate wood than… (you guessed it) wood. For the front part of the box which shows some serious damage I will use balsa wood. Balsa is very soft and extremely easy to work with. You can easily shape it with your hobby knife.

For the rest of the crate I wanted to use something that have a natural wood texture. Veneer is an obvious choice here. It is, again, very easy to work with and has some very realistic structure. And it is really cheap. A couple of years ago I went for a scavenge hunt to my local carpenter and he was kind enough to give me a lifetime supply of veneer leftovers for free!

I started with the balsa part carefully cutting out the damage visible on the photo. It’s super easy. The part you see on the pic below was actually a training piece that came out well enough that I decided to keep it on my build.

Here is the complete set of parts for my ammo crate. For the lower part I will use a piece of styrene plastic for stability.

And here are the parts glued together. I used a CA glue to work fast, although it’s not the ideal option for wood.

I recreated a bit of the inside of the crate as well. But let’s face it: nobody is going to see it.

It’s time to add some details. I used plastic strips and some random PA parts during the process. Side handles were made with wire. Again, take your time building up the details on your scratch-build parts. It is always going to pay off during the painting.

The next steps are the tracks. I’ve worked with MasterClub products many times and I’ve never had problems before. But this time the tracks felt a little bit stiff. I had to use a needle to ensure a good connection between links. But all in all, the tracks came out great.

As always in this kind of repetitive job, I divided the building process into a couple of sessions just to avoid going insane.

TAKOM was thoughtful enough to design the inside of the wheel hub, so you have the option to leave the cap missing. It’s not really a realistic scenario but definitely looks cool, so I went for it. I only had to deepen the holes with a drill.

I think it’s high time to wrap the construction up, isn’t it? The last thing I made (and I wasn’t really looking forward to) was the ammunition. TAKOM decided to mould the rounds together with the mounting racks. It makes the construction easier, but the painting will in turn be much more complicated. The other downside is that you can’t easily make some of the racks empty. It’s either the whole stack or recreating the empty racks from scratch. At that point I was really tired with the whole building process so I went with the first option.

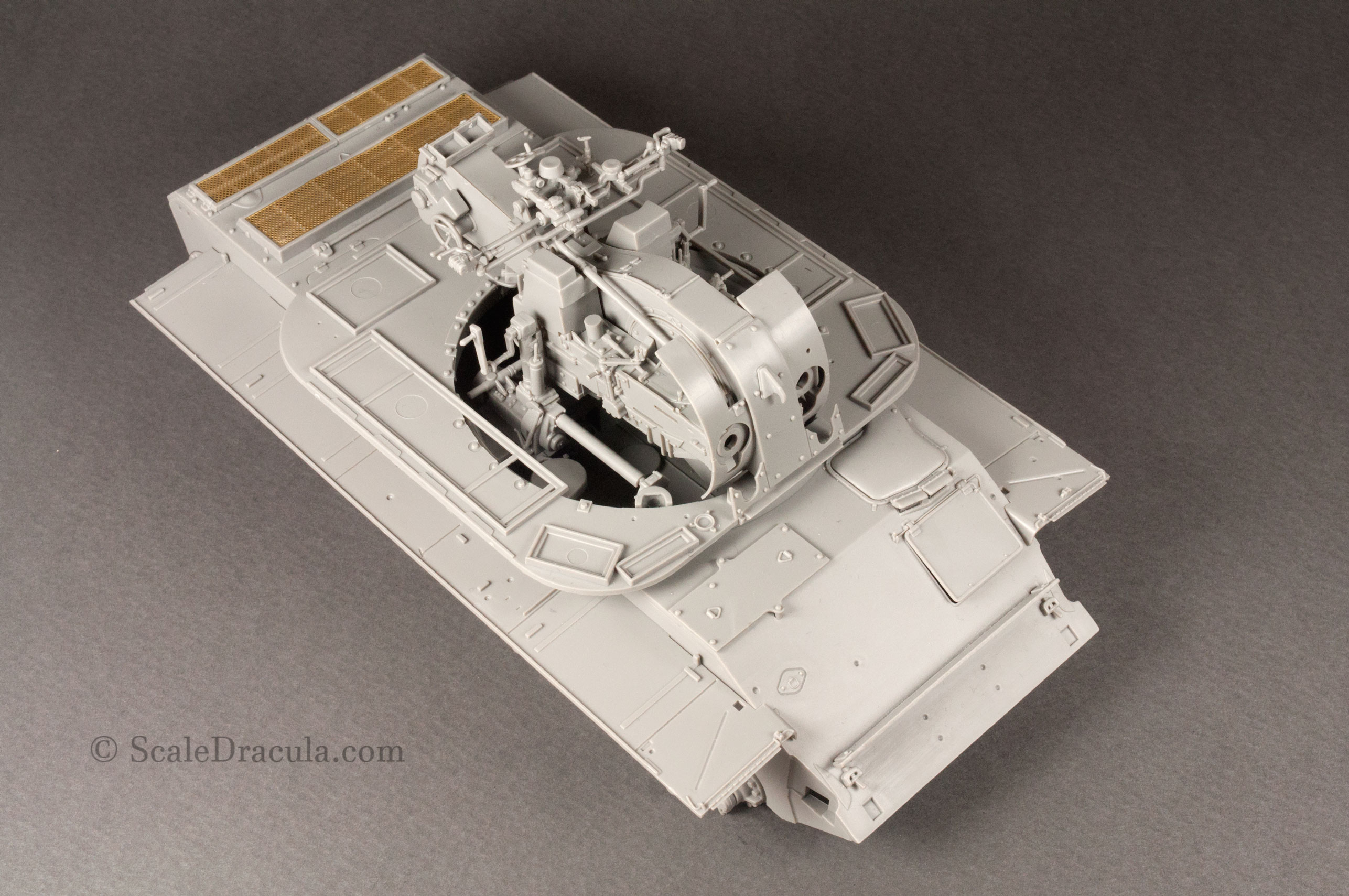

And here’s the whole set just begging for some paint. I obviously haven’t glued the turret yet for easier approach.

Hold on, there’s one thing missing, isn’t it? Do you remember a tarp at the back of the turret I talked about earlier?

I’ve mentioned it’s probably a machine gun on a AA mount covered with a tarp. Or… maybe not? I just don’t care. I’m really done with this construction process and I just want to start painting. Maybe I’ll come back to the machine gun later.